When you're swiping your favourite lipstick in the morning, do you ever wonder how it's made? From choosing the ingredients that make up the best formulas to moulding the lipstick into the ideal shape, a lot of work goes into one lip colour. I was lucky enough to go behind the scenes with Boots for a look at how its No7 lipsticks are formulated [1]. Armed with my lab coat and protective goggles, I had the chance to pour my very own red lipstick and learn exactly what goes into the process of creating this must-have beauty buy. And while the early-stage process I saw was quite hands-on (it's sped up in mass manufacturing using machines), it was interesting to discover how those perfectly shaped bullets of colour make their way from science lab to makeup bag. Take a look at our behind-the-scenes shots for a peek at how your fave Boots lipsticks make it onto the shelves.

First up, it's time to decide on a formula. Various essential oils, emollients, and conditioners go into lipsticks in different concentrations. These vary from natural extracts (like shea butter) to vitamins to texture-based ingredients like film formers and gels. The exact mix depends on the formula; moisturising lipsticks and shiny formulas contain very different ingredients from matte, long-lasting formulas. Boots does extensive customer research to come up with the exact concentrations for each product.

The ingredients chosen in step one are then added to a standard lipstick base, in this case vegetable wax. This is solid at room temperature but melts very easily. The wax and other ingredients are gently heated up to form . . .

. . . a thick paste, your lipstick base, which at this point is colourless and a little like lip balm.

The next step is to roll out the lipstick base and add the pigment (which comes in powder form). For this, you need a metal roller machine and a spatula.

The waxy lipstick base is fed into the roller at the top, where it is slowly rolled through to the front, where it becomes softer and more malleable.

The wax base is gently scraped off the front and fed back into the roller, but this time small amounts of the pigment are poured in at the same time. You keep adding small amounts of pigment to the base as you feed it back into the roller. The whole process can take some time, as it's important to ensure the pigment is perfectly distributed throughout the base so the lipstick is uniform in colour.

Eventually, all the product coming out of the bottom of the roller is the perfect shade of rich red, and you're ready for the next step.

Next up, the lipstick formula is scraped into glass jugs and warmed in a microwave to a high temperature. The lab technicians check the temperature to ensure it's the perfect consistency ready for pouring.

Then, into the moulds we go! This may not look lipstick shaped, but as the pigment cools down, it will pour down into the centre of the mould, which contains a bullet-shaped indent.

Here are our hand-poured single lipstick moulds ready to cool.

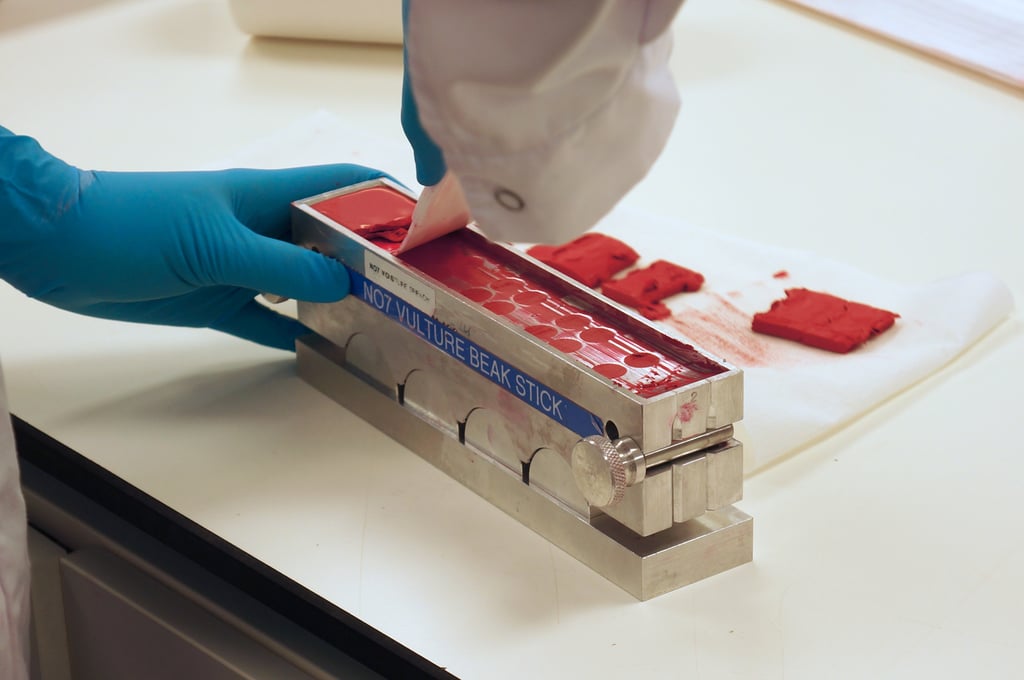

For speed, batches are made in bigger moulds and chilled until they're ready to be potted up. Here you see the excess being scraped off the top of a big mould, revealing the base of dozens of red lipstick bullets.

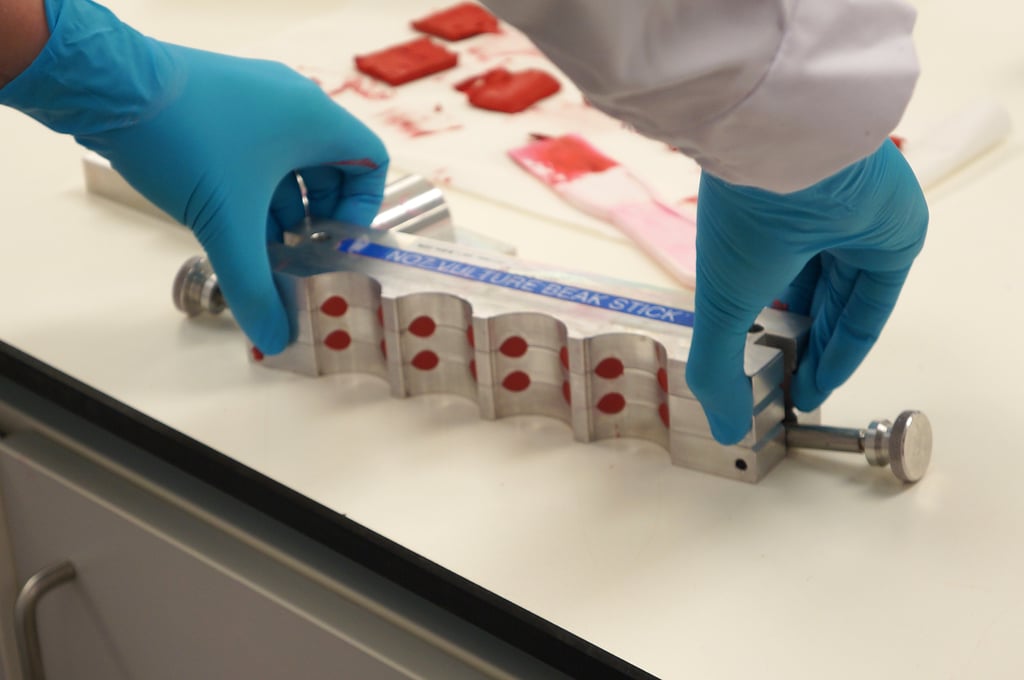

From the centre of the mould with the base removed, you can see the perfect smooth edges of the lipstick tips.

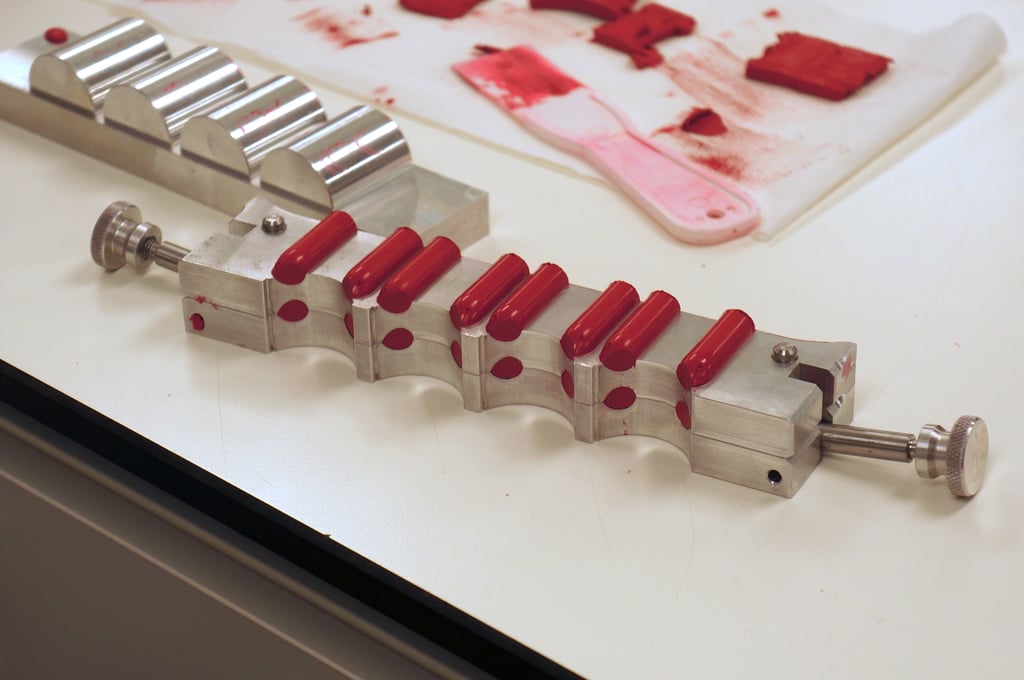

Gentle hands are needed to slowly remove the different sections of the metal mould to reveal all those perfectly shiny lipstick bullets.

These bullets of colour are very gently "popped" out of the mould by pushing downwards from the tip. They then go straight into lipstick tubes, pressed downwards until they feel secure.

Et voilà! The final product is ready to go. We made a special red version of No7 Match Made Moisture Drench Lipstick [2] (£10).

Obviously during manufacturing, a lot of the processes shown above will be done by machinery in much bigger amounts, but the process is still the same: create a lip-friendly base, add pigment, pour it into a mould, chill it, then pop it out and into tubes ready to sell!